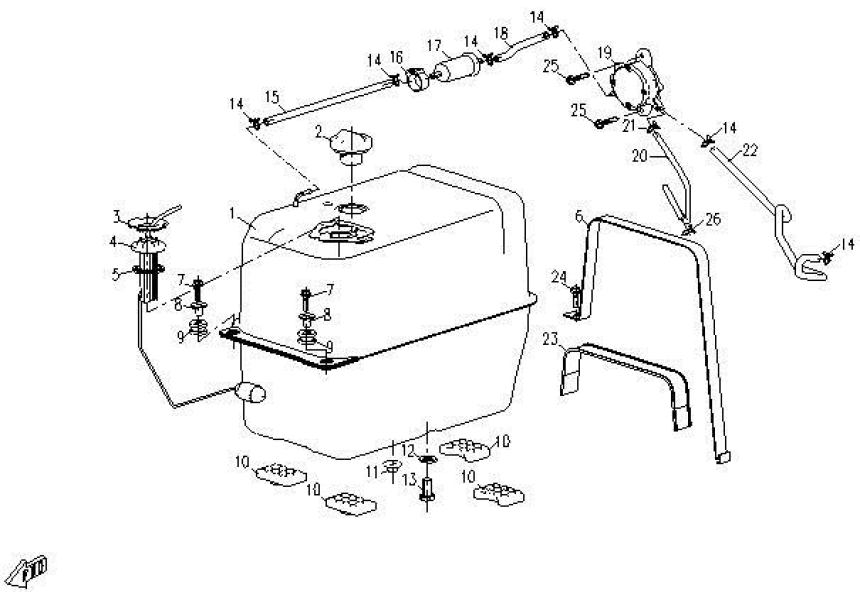

FUEL TANK

ATV Fuel Pump Maintenance & Diagnostic Guide

Complete manual for all-terrain vehicle fuel system troubleshooting, maintenance, and repair.

Fuel Pump Failure Symptoms & Diagnostic Process

Identification and troubleshooting methods for common ATV/UTV/SSV fuel pump problems.

Safety First: Always work in a well-ventilated area, away from sparks or open flames. Fuel is highly flammable. Disconnect the battery negative terminal before working on electrical components.

Common Symptoms of Fuel Pump Failure:

Diagnostic Flowchart (Where to Start Checking):

Step 1: Basic Checks

Step 2: Electrical System Check

Step 3: Fuel System Pressure Test

Common Fuel Pump Problems & Solutions:

| Problem / Symptom | Probable Cause & Solution |

|---|---|

| No fuel pump sound when turning ignition ON | Cause: Blown fuse, faulty relay, wiring issue, pump failure Solution: Check fuse/relay first. Measure voltage at pump connector. If no voltage reaches pump, check wiring and ECU. |

| Pump runs but no pressure or low pressure | Cause: Clogged filter, restricted line, worn pump, clogged pump intake strainer Solution: Replace fuel filter. Check lines for restrictions. Clean or replace pump intake strainer. |

| Intermittent operation (works sometimes) | Cause: Poor electrical connection, failing pump, thermal protection Solution: Check all connectors for oxidation/corrosion. Test immediately when failure occurs. |

| Unusually loud buzzing or whining noise | Cause: Pump running dry, worn pump, cavitation Solution: Ensure sufficient fuel. If noise persists, replace pump. |

| Engine starves for fuel under heavy load | Cause: Insufficient pump output, restricted fuel flow, clogged filter Solution: Test fuel pressure under load. Replace filter and/or pump. |

Fuel Pump Maintenance Procedures

Preventive maintenance measures to extend the life of your ATV fuel pump and fuel system.

Pro Tip: Most fuel pump failures are caused by frequently running the tank empty. Fuel helps cool and lubricate the pump. Try to keep the tank at least 1/4 full.

Regular Maintenance Schedule:

| Interval / Condition | Maintenance Task |

|---|---|

| Every 100 hours or annually | Inspect fuel lines for cracks, leaks, or aging. Check all clamps and connections. |

| Every 200 hours or 2 years | Replace fuel filter (more often if riding in dusty conditions or with questionable fuel quality). |

| Every 500 hours or 5 years | Consider inspecting fuel pump and cleaning pump intake strainer (if serviceable). |

| When storing for >3 months | Add fuel stabilizer and run engine for 5 minutes to circulate treated fuel through system. |

| After water fording or submersion | Immediately check fuel system for water contamination. Drain if necessary. |

| After every fuel pump replacement | Thoroughly clean fuel tank to remove any contaminants. Replace all related seals. |

ATV Fuel Pump Replacement Guide:

Preparation:

Removal Steps:

Installation Steps:

Important: Always use OEM or high-quality replacement parts. Cheap aftermarket fuel pumps often have shorter lifespans. When replacing a failed pump, always thoroughly clean the fuel tank to remove all contaminants.

Fuel System Cleaning & Care:

Fuel Pump Testing Methods

How to properly test your ATV fuel pump using basic tools.

Typical Fuel Pump Technical Parameters:

Electrical Tests (Multimeter Required):

Resistance Test (Bench Test):

Voltage Test (In-Vehicle Test):

Current Test:

Mechanical / Flow Tests:

Flow Test:

Pressure Test (EFI System):

Testing Tip: Always compare test results against manufacturer specifications. Fuel pump performance can vary with temperature and voltage. For accurate results, ensure battery is well charged (at least 12.6V) during testing.

Troubleshooting Quick Reference:

| Test Result | Interpretation |

|---|---|

| No voltage at pump connector | Check fuse, relay, wiring, ignition switch, ECU |

| Voltage present but pump doesn't run | Pump failed, bad ground, seized pump |

| Pump runs but no/low pressure | Clogged filter/strainer, restricted line, weak pump, faulty pressure regulator |

| Pressure drops quickly after shutdown | Leaking injector, failed internal check valve, external leak |

| Pressure too high | Faulty pressure regulator, restricted return line |

| Image/No | Product | Price |

|---|---|---|

| 04 |

Fuel Level Sensor Assy

|

|

| 05 |

Fuel Level Sensor Seal Ring

|

|

| 09 |

Fuel Tank Rear Cushion Sleeve

|

|

| 17 |

Fuel Filter

|

|

| 01 | MICF9030-121000 | |

| 02 | MICF8010-120400 | |

| 03 | MICF5020-120401 | |

| 06 | MICF9030-120001 | |

| 07 | MICF30006-060025840 | |

| 08 | MICF9010-120310 | |

| 10 | MICF6060-120001 | |

| 11 | MICF9030-120002 | |

| 12 | MICF8010-120101 | |

| 13 | MICF30004-123025840 | |

| 14 | MICF30601-109010 | |

| 15 | MICF9030-120510 | |

| 15 | MICF9030-120510-1000 | |

| 16 | MICF8010-120001 | |

| 18 | MICF9030-120520 | |

| 18 | MICF9030-120520-1000 | |

| 19 | MICF9030-120600 | |

| 20 | MICF9030-120530 | |

| 20 | MICF9030-120530-1000 | |

| 22 | MICF9030-120540 | |

| 23 | MICF5190-020102 | |

| 24 | MICF30006-060016840 | |

| 25 | MICF30006-060020840 | |

| 26 | MICF30601-110030 | |

WhatsApp

WhatsApp

Messenger

Messenger

Telegram

Telegram

WeChat

WeChat

QQ

QQ